Compressed Air Dryers

Delivers low dew point air with zero air loss — ideal for point-of-use, intermittent flow applications.

Moisture Is the Hidden Threat in Every Compressed Air System

Keep Your Tools and Equipment Running at Peak Performance

Single-Tower Compressed Air Dryers

-

D1 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

Regular price $1,095.00 USDRegular priceUnit price / per -

D2 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

Regular price $1,825.00 USDRegular priceUnit price / per -

D3 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

Regular price $2,295.00 USDRegular priceUnit price / per -

D4 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

Regular price $3,125.00 USDRegular priceUnit price / per

Wet air can cause serious problems in manufacturing processes and operations.

-

Damaged Tooling

Rust and wear of pneumatic machinery, hand tools, and equipment.

-

Product Contamination

Corrosion, spoilage, or defects in moisture-sensitive products.

-

Control Malfunctions

Freezing of outdoor air lines, clogged valves, and unreliable operation.

-

Poor Paint Finishes

Bubbles, blisters, and other imperfections in painted surfaces due to moisture.

-

Increased Rejects

Higher scrap rates, resulting in lost revenue and reduced productivity.

Powering Industry-Specific Needs

-

Manufacturing

By removing moisture and contaminants, a compressor air dryer helps prevent corrosion...

-

Sand Blast

Using an air dryer in conjunction with a sandblasting setup can be...

-

Paint Shop

An air dryer in a paint shop is a crucial component of...

-

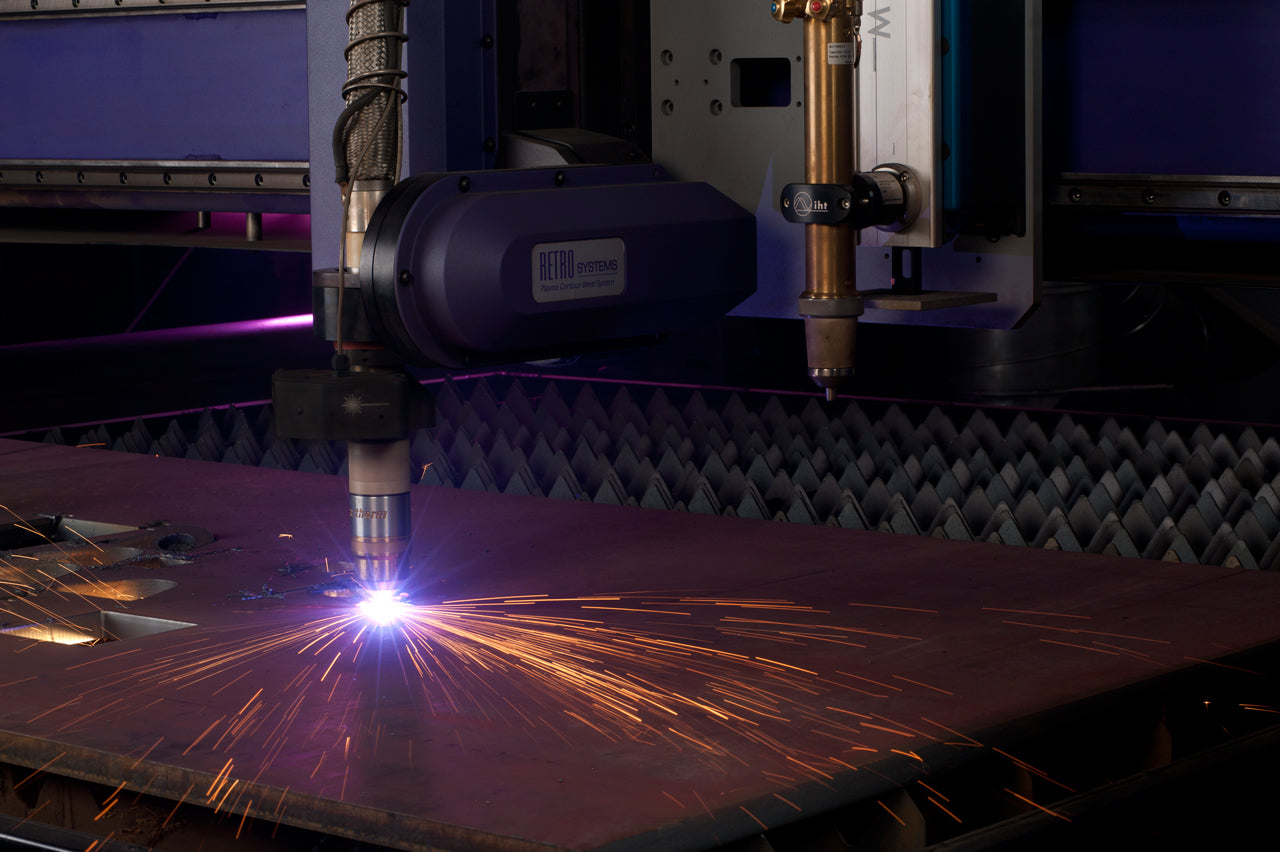

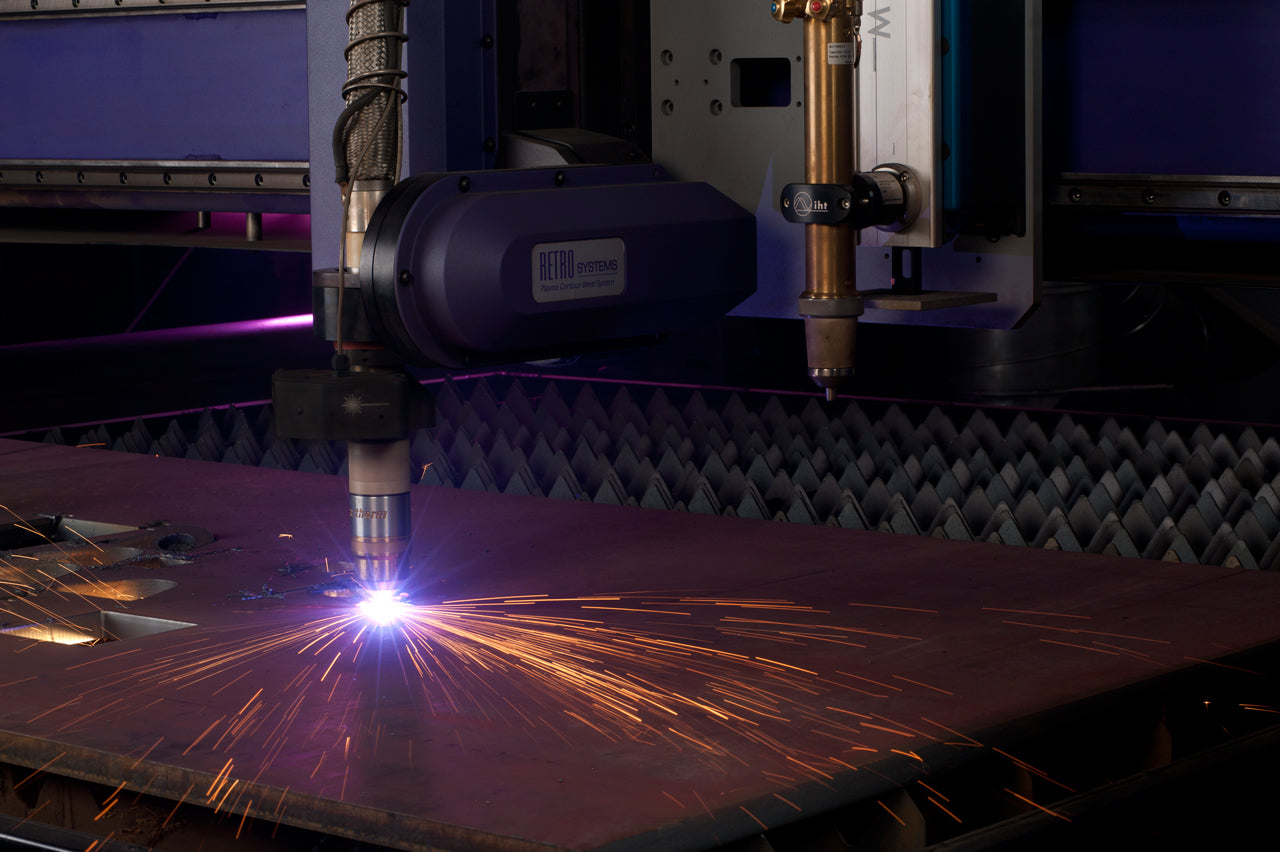

Plasma Cutting

Compressed air often contains moisture, which can negatively impact the performance of...

-

Dust Collectors

Compressed air often contains water vapor, and when the air cools, this...

-

Nail Guns & Air Tools

An air tool air dryer, also known as a compressed air dryer,...

-

Diesel Compressor

A diesel compressor air dryer is a system used to remove moisture...

-

Ready-Mix Concrete

Moisture in compressed air is a hidden threat in cement production. It...

-

Medical & Pharmaceutical

In the medical and pharmaceutical industries, the quality of compressed air is...

-

Underground Wires

Dry compressed air is essential when installing underground electrical cables and fiber...

-

Food Processing

In the food and beverage industry, clean and dry compressed air is...

Why Choose Super-Dry Air - Dryers Engineered for performance, reliability, and efficiency.

-

Reliable Air Quality

Delivers clean, dry compressed air that meets ISO 8573-1 standards. Protects tools, valves, and instruments from moisture damage and contamination.

-

Lower Operating Costs

Prevents corrosion, leaks, and filter overload. Reduces compressor energy use and extends equipment life — saving money every day.

-

Built for Industrial Demands

Rugged, compact, and maintenance-friendly design for 24/7 reliability in harsh shop environments. Ideal for CNC, paint, and packaging operations.

Engineered for Reliable, Dry Air — Every Time

At Super-Dry, we help manufacturers eliminate moisture problems that cause corrosion, downtime, and product defects. Our point-of-use air dryers are built for industrial reliability, ISO 8573-1 compliance, and low maintenance operation. With over 25 years of engineering experience, we make it easy to get clean, dry air where it matters most — keeping your equipment efficient and your production uninterrupted.

Who We've Helped

⭐ ⭐ ⭐ ⭐ ⭐

" It is a privilege doing business with a company that has the answers to my questions and concerns about a great product that really speaks for itself. Thanks again".

Mike Salazar, Owner, Double M Energy

Get Help Choosing Your Desiccant Air Dryer

Take our quick online quiz — it only takes a minute to find the perfect Super-Dry system for your setup. Get personalized recommendations based on your air flow, pressure, and application.