Super-Dry Systems

D2 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

D2 - Single-tower desiccant compressed air dryer, aluminum housing, with activated alumina desiccant

SKU:280-120

34 in stock

Shipping & Delivery

Shipping & Delivery

We offer fast, reliable shipping worldwide. Orders are processed within 1-2 business days; Express shipping does not accelerate the order processing.

Professional Installation Recommended

Professional Installation Recommended

Super-Dry products deliver reliable results when installed under proper system conditions. If you’re unsure about your setup, we recommend having a local compressed air specialist review your system before installation. Super-Dry does not provide on-site support.

Tariff Surcharge

Tariff Surcharge

All shipments to the United States include a 10% Tariff Surcharge. The surcharge is a temporary measure to offset part of the tariffs currently applied to our products.

DESCRIPTION

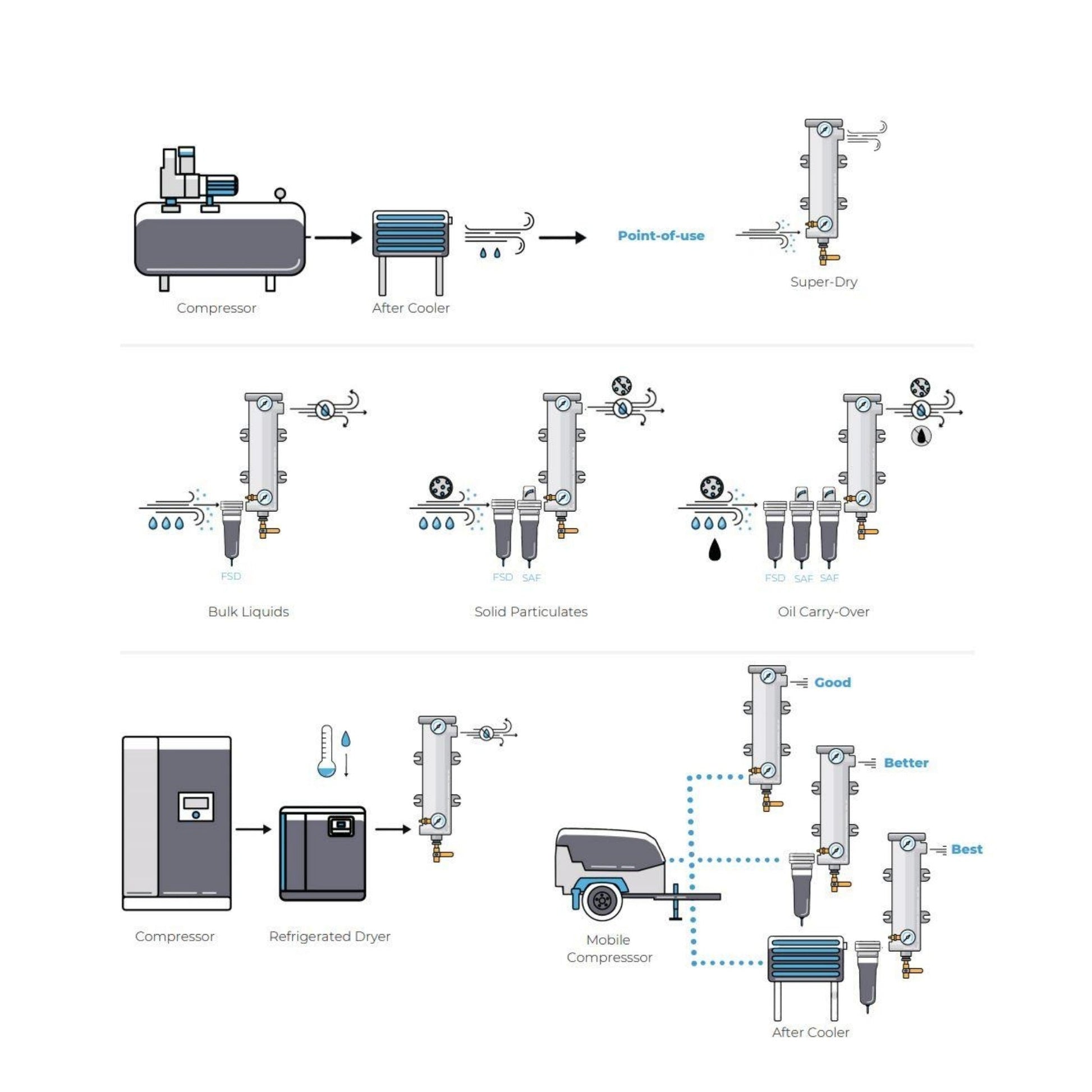

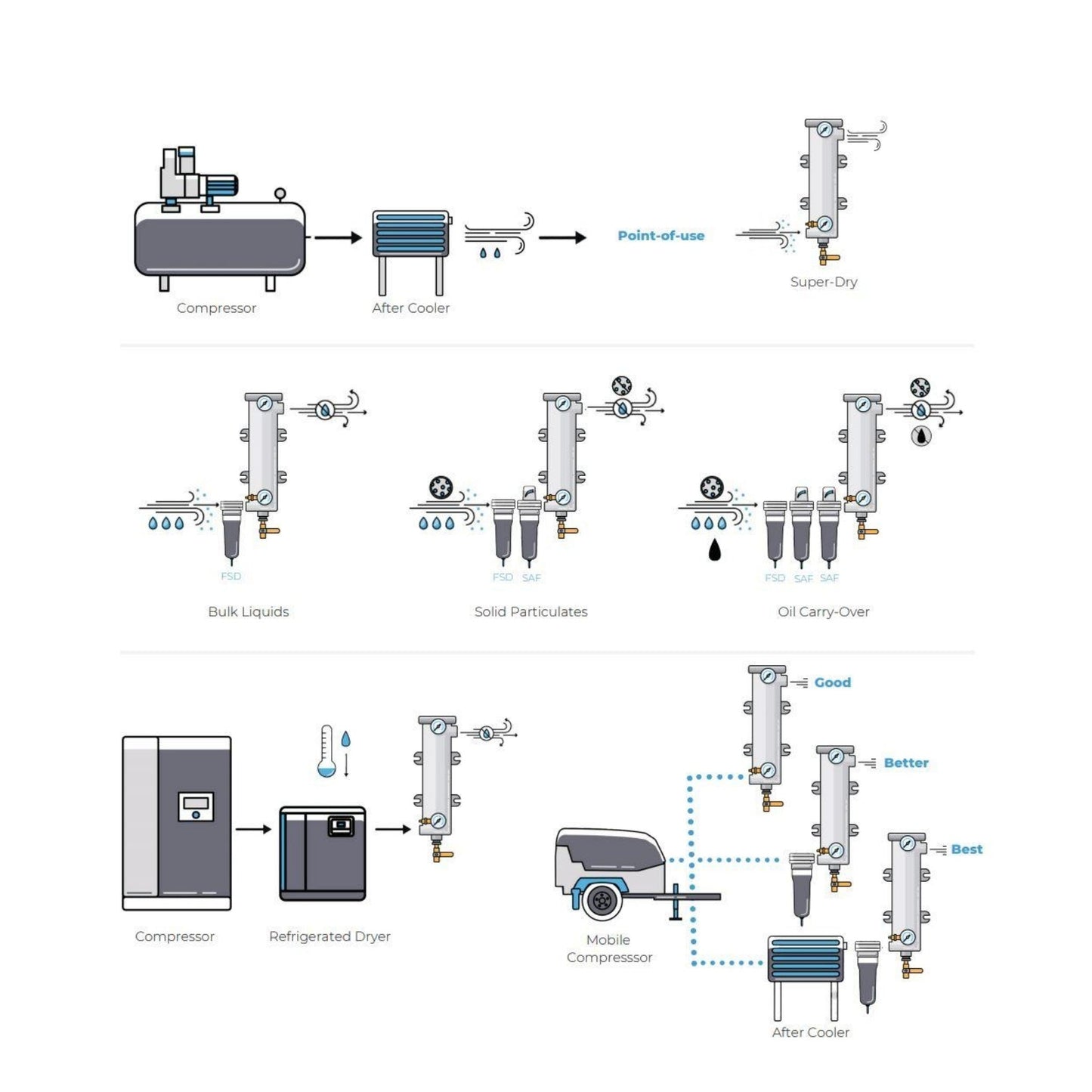

The D Series is a single tower desiccant air dryer designed for point-of-use and intermittent flow applications. The wet compressed air enters at the inlet, is first separated due to the off-set inlet creating centrifugal separation to trap water droplets, and subsequently passes around a polypropylene coalescer element, felt pads, and stainless-steel grids to remove solid particulates. The air flows upward through a sewed filtration desiccant bag that acts as a sponge to absorb moisture. Finally, the air flows again through the second stage of filtration to eliminate any desiccant dust. This 3-stage system efficiently provides separation, filtration, and drying. It is time to replace the cartridge when the Moisture Gauge indicates saturation. The replacement is fast and mess-free, thanks to the US stainless-steel clamp. The rust-free powder-coated aluminum housing is made in Canada and includes built-in brackets.

✅ Professional Installation Recommended

Super-Dry air dryers are factory-engineered and time-tested for dependable performance when installed under proper compressed air system conditions.

If you’re not fully familiar with compressed air best practices, we recommend contacting a local compressed air specialist or service technician who can review your setup before installation.

💡 Important: Many performance issues arise from system conditions — such as overheating compressors, excessive moisture, or incorrect piping — that no air dryer can solve alone.

Super-Dry is a manufacturer and does not offer on-site service or system troubleshooting. Ensuring proper installation will help your dryer perform as designed and provide lasting reliability.

A superior alternative to Devilbiss DAD 500, Camair CT30, MP Filenco, Van Air Moisture Block.

SPECS

- INLET / OUTLET PORTS: 1-1/2'' NPT

- AIRFLOW @ 100 PSIG: 150 SCFM

- MAXIMUM INLET PRESSURE: 150 PSI

- MAXIMUM INLET TEMPERATURE: 100°F (38°C)

- CRN: CERTIFICATIONS & PRESSURE RATINGS

- PRE-FILLED WITH DESICCANT CARTRIDGE

- PRESSURE GAUGES, SAFETY VALVE, AND BALL VALVE INCL.

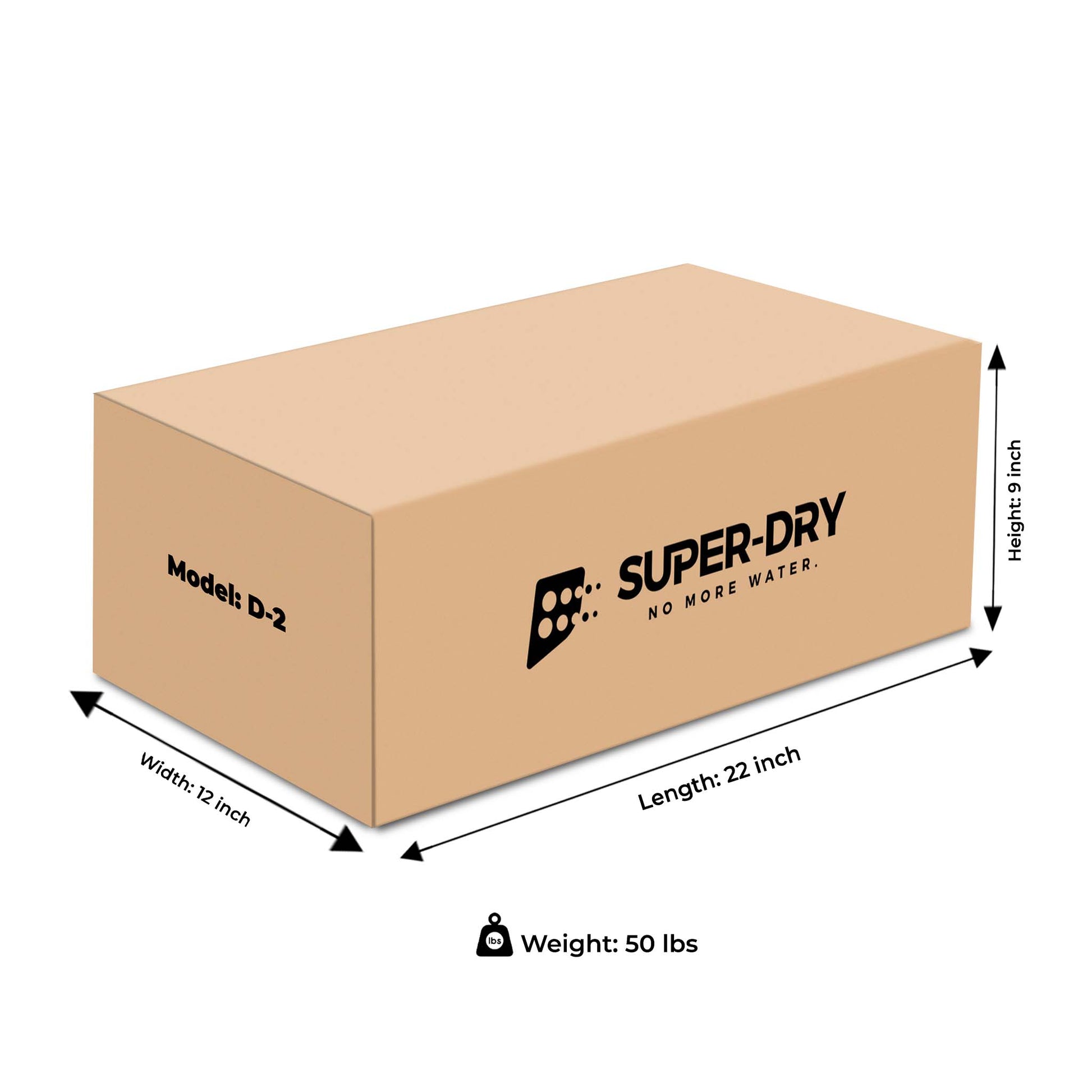

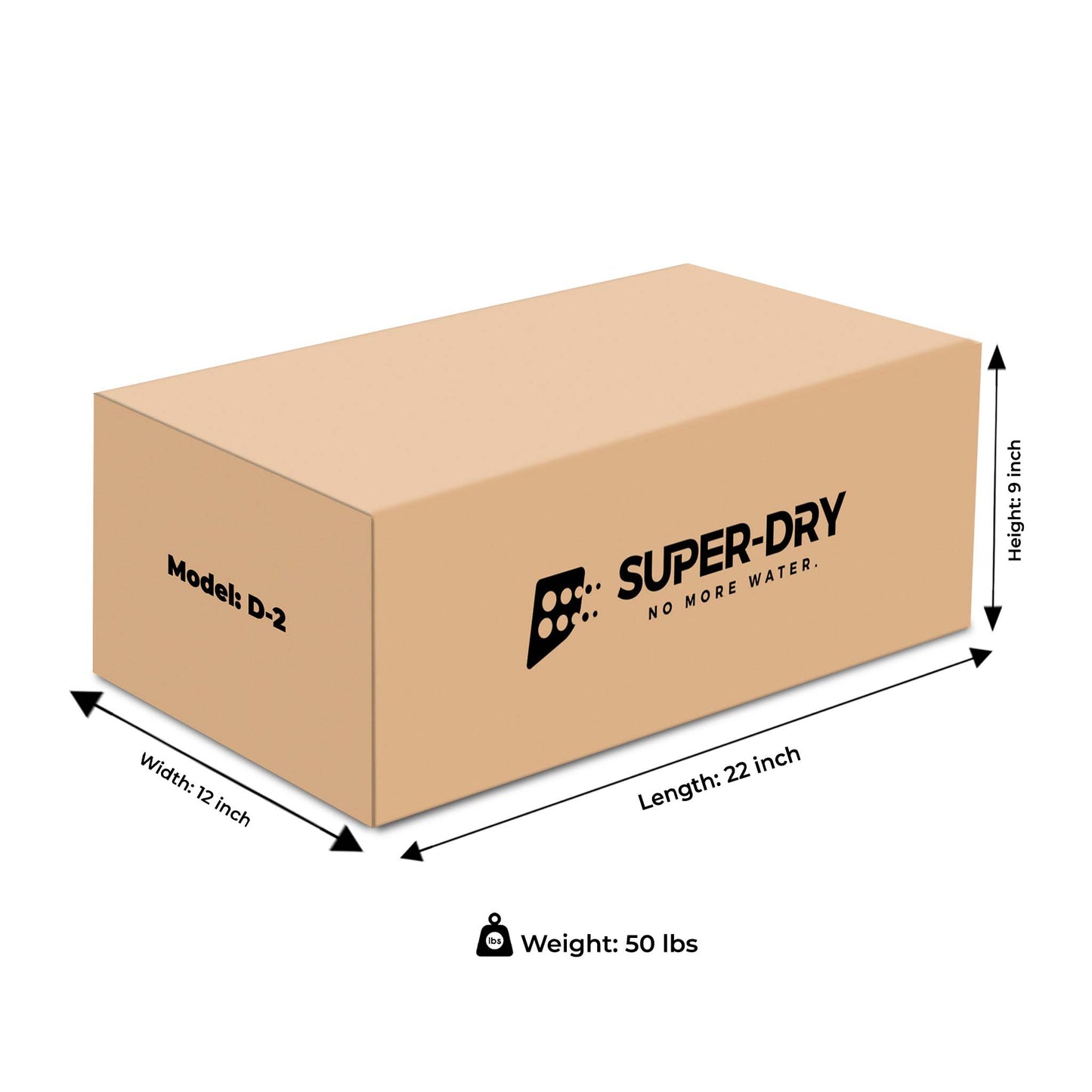

- UNIT WEIGHT: 50 LB

- BOX DIMENSIONS: 22 x 12 x 9"

- DESICCANT BAG APPROX. WEIGHT: 10 LBS

FAQ

1. How long does the cartridge last?

Typically, we recommend changing the cartridge at least once to twice every year (or every 2,000 hrs) when used for point-of-use applications with an intermittent flow. You can estimate the cartridge's life by using our Cartridge Life Calculator.

2. When do I know when to change the cartridge?

Use our moisture indicator HGT-1/4 and replace the cartridge when the R.H. exceeds 80%.

3. Can I regenerate the desiccant?

We highly recommend replacing the desiccant with a fresh cartridge for optimal performance. However, you may dry the desiccant by emptying the bag and leaving the activated alumina in an oven at 275 F for 4 hours (approximately). Let the desiccant cool down before refilling the bag. Use a commercial stapler to close the bag.

4. How can I extend the life of the cartridge?

We recommend draining the tower daily by opening the ball valve or using our automatic timer drain TD-1/4. When there are bulk liquids in the compressed air, a water separator FSD Series installed upstream of the dryer will knock water and prevent the flooding of the cartridge.

5. Can I oversize my air dryer?

Yes, oversizing the air dryer will increase the time in between maintenance.

To ensure that Super-Dry is the right fit for your application, we recommend that you take our Online Quiz to help you identify the right model for your application.

7. Can I obtain a stable -40° F Dew Point?

No. The D series is a single tower non-renegerative air dryer. As a result, the -40° F Dew Point can’t be maintained. We know that some competitors advertise -40° F Dew Point, however they can’t provide any third party tests that supports their claim. In other words, if you need a -40° F Dew Point, you need a twin tower regenerative air dryer, period. We currently don’t manufacture these types of air dryers.

8. What Dew Point should I maintain?

Like most single-tower air dryers, the dew point will decline over time. Once installed, some users will reach -40° F for a short period (a couple of hours). After a few days, it will go down to -20° F to +20° F (still below the freezing point). In other words, a twin tower must be used if the customer requires a stable dew point of -40 ° F Dew Point.

Share

Get Help Choosing Your Desiccant Air Dryer

Take our quick online quiz — it only takes a minute to find the perfect Super-Dry system for your setup. Get personalized recommendations based on your air flow, pressure, and application.